colorFabb VS. Proto-pasta

Which one should you get first?

So, during the development of DSLRigger, my Open-source camera project I worked with carbon fiber filaments and got two different deliveries. I wasn’t sure on which one to use so i decided to to a proper test of them.

As you can see in the video above, the result was pretty similar. Sure, one is easier, but the other one adds some extra functionality due to it’s recipe.

I hope you enjoy the test. Drop us a comment if you have any questions at all!

The test includes the two following materials:

colorFabb XT-CF20 and Proto-pasta HTPLA – Carbon Fiber

During testings I ran the two different materials in a few different machines.

Magicfirm – ZYYX (briefly)

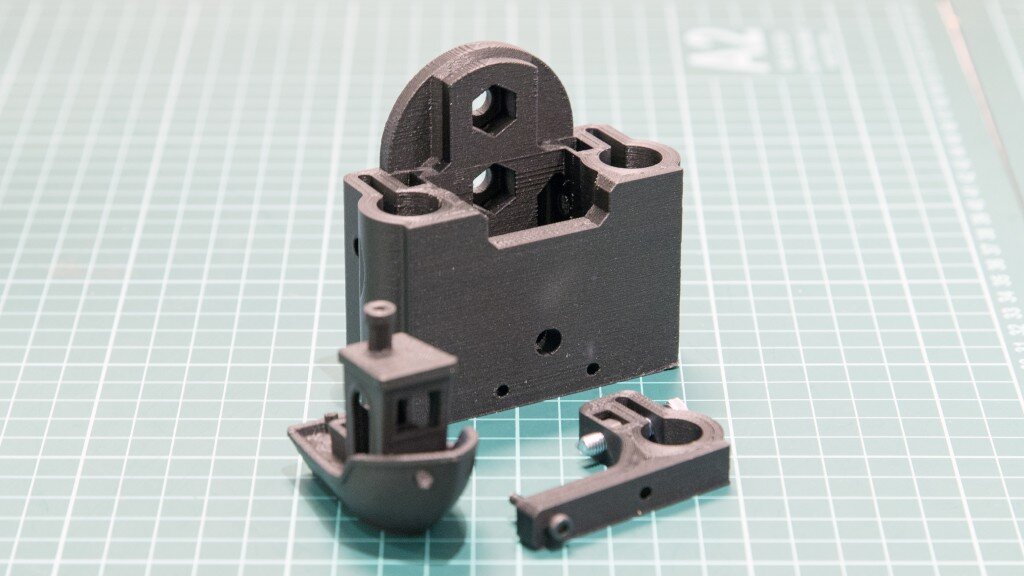

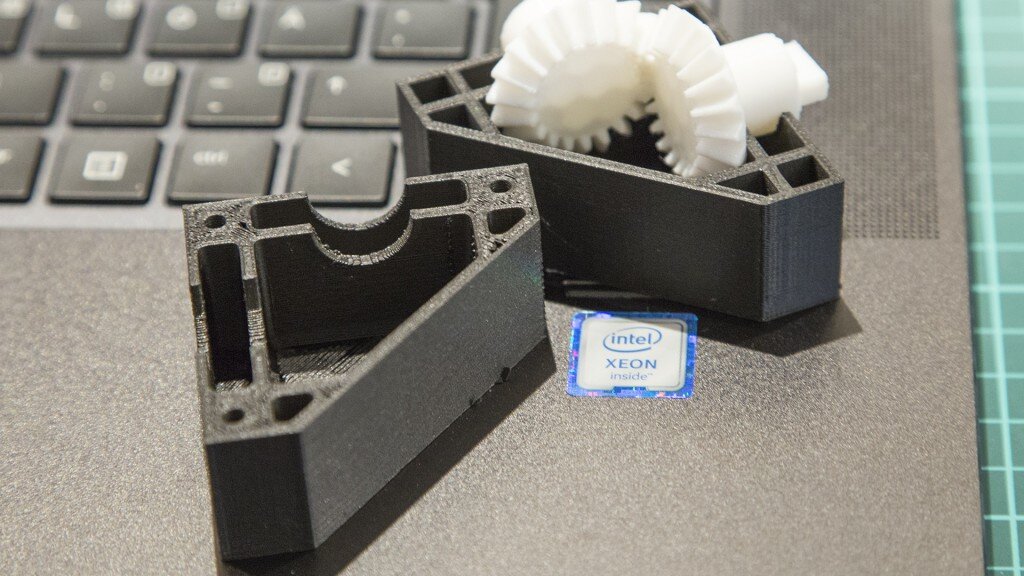

The parts we used for testing were mainly from my DSLRigger project, but of course we also included the 3Dbenchy benchmarking model.

The result (as you can see in the video) is very depending on the actual settings you use. For me, I fel that the Proto-pasta filament was so much easier to use and the result felt as strong as needed.

The parts i’ve printed have been very resistant to pressure and wear. Some of the parts on my camera rig is clamping rods, and the filaments both resists high pressure for long duration, even with stress involved.

ColorFabb XT-CF20 Specifications

ColorFabb XT-CF20 is a copolyester based carbon fiber composite material that is based on the unique Amphora 3D polymer from Eastman Chemical and is loaded with no less than 20% specially sourced carbon fibers suitable for 3D Printing

Extreme High Flex Modulus (6.2 GPa) / twice as stiff as PLA

Moderate strain at break (8-10%), so no extreme brittle filament, but toughness

High Glass Temp. (Tg = 80C)

Very high Melt strength

Very high Melt Viscosity

Good dimensional accuracy and stability

Low odor / Styrene Free solution

Easy processing on many platforms

High attractive matt black surface

Proto-pasta Specifications

Compared to ABS, PET, and similar Polyester materials, HTPLA-CF has:

Easier and more reliable printing

No heated bed required

Lower processing temperatures, like standard PLA

Less warping and distortion when processing

More temperature resistance* for maintaining properties to higher temperatures

Most ABS, PET, and Polyesters get soft at 80C +/- 10C

HTPLA-CF maintains properties up to 120C or more (*when heat treated)

Higher strength and better strength-to-weight ratio for stronger parts with less material

Improved surface hardness for less wear in abrasive environments

Less shrinkage and distortion for more accurate parts

Higher stiffness so parts hold their shape

Renewable biopolymer with low odor

Highly desirable black finish

HTPLA-CF, like Aromatic Coffee, is based on High Perfomance HTPLA v2.0, so it prints easily and can be heat treated for higher temperature performance with a potential Heat Deflection Temperature (HDT) in excess of 140C (285F) depending on processing. We had good results when heat treating in an oven at 110C (225F) for an hour. We recommend leaving the supports on your parts, placing them on a non-radiating surface (like glass, ceramic, or composite), and letting them cool in the oven to minimize distortion. Parts must be baked above 60C for any crystallization to occur.

Colorfabb results

Strength 90%

Flexibility (not relative) 15%

Compability (machines) 65%

Ease-of-use (settings) 50%

Adhesion to build surfaces 70%

Proto-pasta results

Strength 90%

Flexibility (not relative) 10%

Compability (machines) 75%

Ease-of-use (settings) 85%

Adhesion to build surfaces 75%