Type A Machines – ProMatte PLA Review

The Review video is of course above, but the whole story can be read below.

My experience with Type A Machines ProMatte is really good, and the whole company for that matter!

The whole story started with me reaching out to Type A machines with some questions about the ProMatte material. I wanted to try out more materials with a matte finish that lets designers get a nice finish without needing to spend hours to post process your print (more on why you still should later). We talked a bit and Tom over at Type A machines decided to send over a reviewer sample for me to conduct a non-biased review as usual. Remember, I don’t sell prints or sell Type A machines filaments, I have no discount code or link-affiliation with them. This is me wanting to learn, share and help the community with knowledge, best practice and unbiased source of help.

We had a little struggle with the shipping at first. US to Sweden isn’t always the best. But after a second package was sent I received the package. I actually ended getting the first package a few weeks later, just after the video was finished. I’ll see if I can’t give those away for

Running it in the Replicator 2, Flashforge dreamer, Flashforge Finder and Duplicator i3. Our MakerBot Replicator Desktop 5th gen was too busy at the moment of testing, I’ll probably end up printing with it there in the future.

Type A Machines recommended settings:

Print Temperature Range: 180-240 ˚C

Heated Bed: 60 ˚C recommended, but not required.

Build Surface Treatment: Glue on Glass

The temperature needs to be adjusted of course, that’s just standard practice for 3D-printing. When you receive a new material you should print a 1x1x1cm cube or a #3DBenchy to see how it behaves and adjust settings (temperature, fan and speed). For the Replicator 2 I ran at 225˚C on extruder, at 45% max power on cooling fan, cold plate (AprintaFix PRO spray on) and around 20-80mm/s depending on feature (outlines 60mm/s, infill 80mm/s and first layer at 20mm/s).

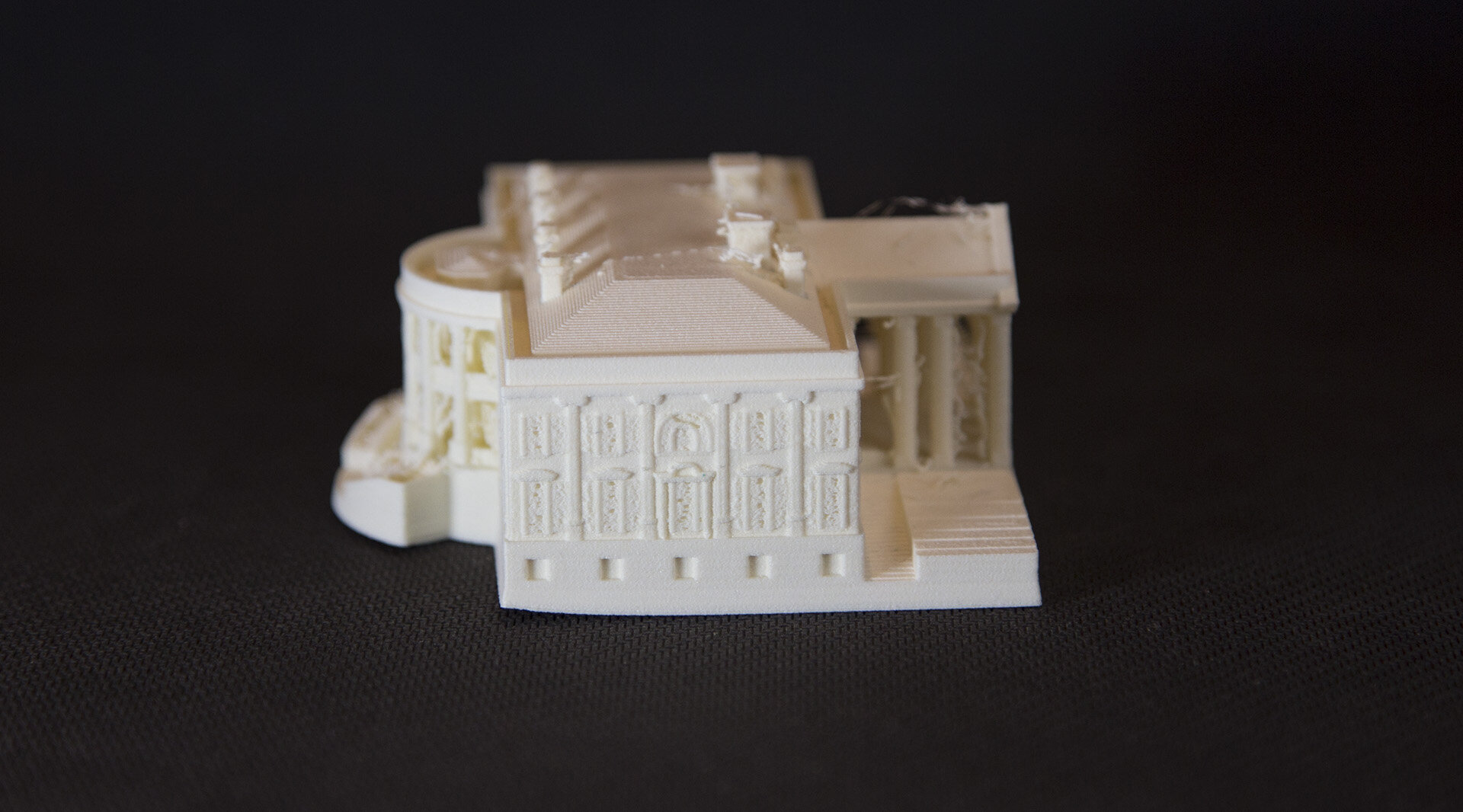

Type A Machines advise not to use strong retraction since it won’t prevent any stringing. I can confirm that I couldn’t do anything really about that. The parts with loads of small details (The White House model below) needs to be cleaned, but most of the other parts you see below are still untouched and still looks good. That stringing won’t be hard to remove. I even tried using a lighter to burn some away, not a good idea. Just a bunch of molten plastic on your hands…

The issue with stringing is true for some sort of models. Vase-models and other models with few retractions will work great. The knee below for example looks amazing!

Replicator 2 – ProMatte PLA

I mentioned above about why you still should spend some time on post processing on your model. My reason for that is that I believe this material to be perfect for sanding or tumbling. On the Low Poly cat below I tried to quickly scrape the edges on a sandpaper and I really like the result. If you want you can spend even more time on the sanding/tumbling to get nice smoothed surfaces.

This materials offer not only a good base line for visual prototypes and even final ornaments/designer models but also a good base for sanding and tumbling as mentioned above. It’s good out of the box, but can become way nice than standard PLA with a bit of work.

Overall I really enjoyed the ProMatte PLA for what it’s designed for. Visually appealing finish with minimum effort, easy to get going with and easy to adjust settings for. I’d wish they would be a bit cheaper but well worth it for customers that do; Design bureaus, Architectural models, Design prototypes, Ornamets, Busts, Scan-copies, landscape and similar.

PRO:

Superb matte finish and looks

Easy to print

Easy to adjust settings for

Nice packaging

CONS:

Could be a bit cheaper (500gr spools)

Could have less stringing

More images here:

If you are curious and wanna learn more, go to Type A Machines for all the juicy info! If you feel like supporting me and my Youtube channel, please consider something of the following:

– – –

The Amazon links acts as a cookie. If you decide to purchase anything that you needed anyways, by using amazon instead of ebay or aliexpress I can get a small kickback (wont affect you or your price)

(— Amazon US – Approved products by 3DpTD – http://bit.ly/3dpTDrec16

(— Amazon US – Referral link – http://bit.ly/Amzn3DtPD16

(— Amazon UK – Referral link – http://amzn.to/29aenPQ

(— Amazon ES – Referral link – http://amzn.to/2abyBbj

Running a YouTube channel is an investment in time and gear. I do this on my spare time and isn’t employed by anyone to do so. If you feel like donating please consider doing so over at https://www.paypal.me/amid2d3d

Thank you very much! Hit me up if there’s anything you wish to know comment here or tweet me @Antonmnsson!